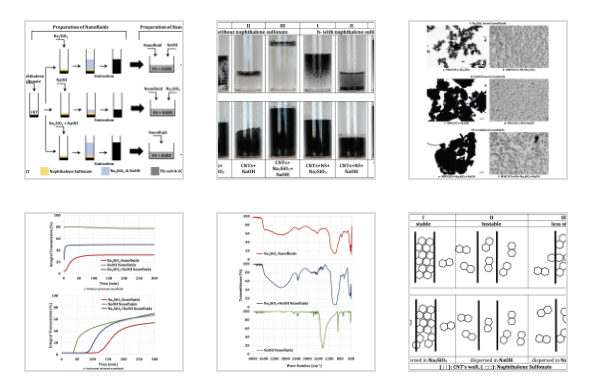

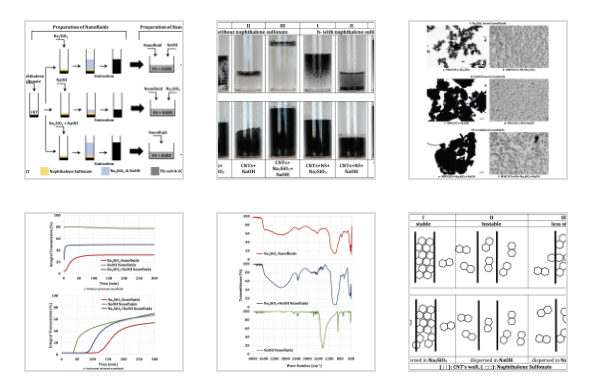

The focus of present research is the establishment of a practical procedure for effective incorporation of multi-walled carbon nanotubes (MWCNTs) into alkali-activated materials (AAMs) with the aim of mechanical reinforcement. Investigated composite in this work was an alkali-activated matrix composed of fly ash (FA) and ground-granulated blast furnace-slag (GGBS) as solid aluminium-calcium-silicate precursors along with highly concentrated sodium silicate (Na2SiO3) and sodium hydroxide (NaOH) as liquid alkaline activators. Na2SiO3, NaOH, and a combination of them were used for dispersion of MWCNTs. An anionic surfactant, naphthalene sulfonate (NS), and ultrasonication were applied to assist in the preparation of nanofluids. Optical microscopy, integral light transmission (ILT), and Fourier-transform infrared spectroscopy (FTIR) were performed to assess the colloidal behaviour of MWCNTs in the nanofluids. The possible dispersion mechanisms were furthermore hypothesised for each alkaline medium. Based on the outcomes, MWCNTs had the best dispersion performance in the Na2SiO3 based nanofluids. The relevant nanocomposites accordingly, in comparison to the other preparation methodologies in this research, indicated the highest improvements in flexural (65%) and compressive (30%) strengths as a consequence of 0.050 wt% MWCNT incorporation. Scanning electron microscopy (SEM) and mercury intrusion porosimetry (MIP) further clarified the reinforcement functionality and microstructure refinement of the MWCNTs dispersed in the Na2SiO3 based nanofluids. Altogether, this paper represents a broad insight concerning a better understanding of MWCNTs’ interactions in alkaline activators, i.e. dispersion media, and AAMs, i.e. host matrices, to obtain the highest possible mechanical and microstructural performance of reinforced nanocomposites.

The focus of present research is the establishment of a practical procedure for effective incorporation of multi-walled carbon nanotubes (MWCNTs) into alkali-activated materials (AAMs) with the aim of mechanical reinforcement. Investigated composite in this work was an alkali-activated matrix composed of fly ash (FA) and ground-granulated blast furnace-slag (GGBS) as solid aluminium-calcium-silicate precursors along with highly concentrated sodium silicate (Na2SiO3) and sodium hydroxide (NaOH) as liquid alkaline activators. Na2SiO3, NaOH, and a combination of them were used for dispersion of MWCNTs. An anionic surfactant, naphthalene sulfonate (NS), and ultrasonication were applied to assist in the preparation of nanofluids. Optical microscopy, integral light transmission (ILT), and Fourier-transform infrared spectroscopy (FTIR) were performed to assess the colloidal behaviour of MWCNTs in the nanofluids. The possible dispersion mechanisms were furthermore hypothesised for each alkaline medium. Based on the outcomes, MWCNTs had the best dispersion performance in the Na2SiO3 based nanofluids. The relevant nanocomposites accordingly, in comparison to the other preparation methodologies in this research, indicated the highest improvements in flexural (65%) and compressive (30%) strengths as a consequence of 0.050 wt% MWCNT incorporation. Scanning electron microscopy (SEM) and mercury intrusion porosimetry (MIP) further clarified the reinforcement functionality and microstructure refinement of the MWCNTs dispersed in the Na2SiO3 based nanofluids. Altogether, this paper represents a broad insight concerning a better understanding of MWCNTs’ interactions in alkaline activators, i.e. dispersion media, and AAMs, i.e. host matrices, to obtain the highest possible mechanical and microstructural performance of reinforced nanocomposites.