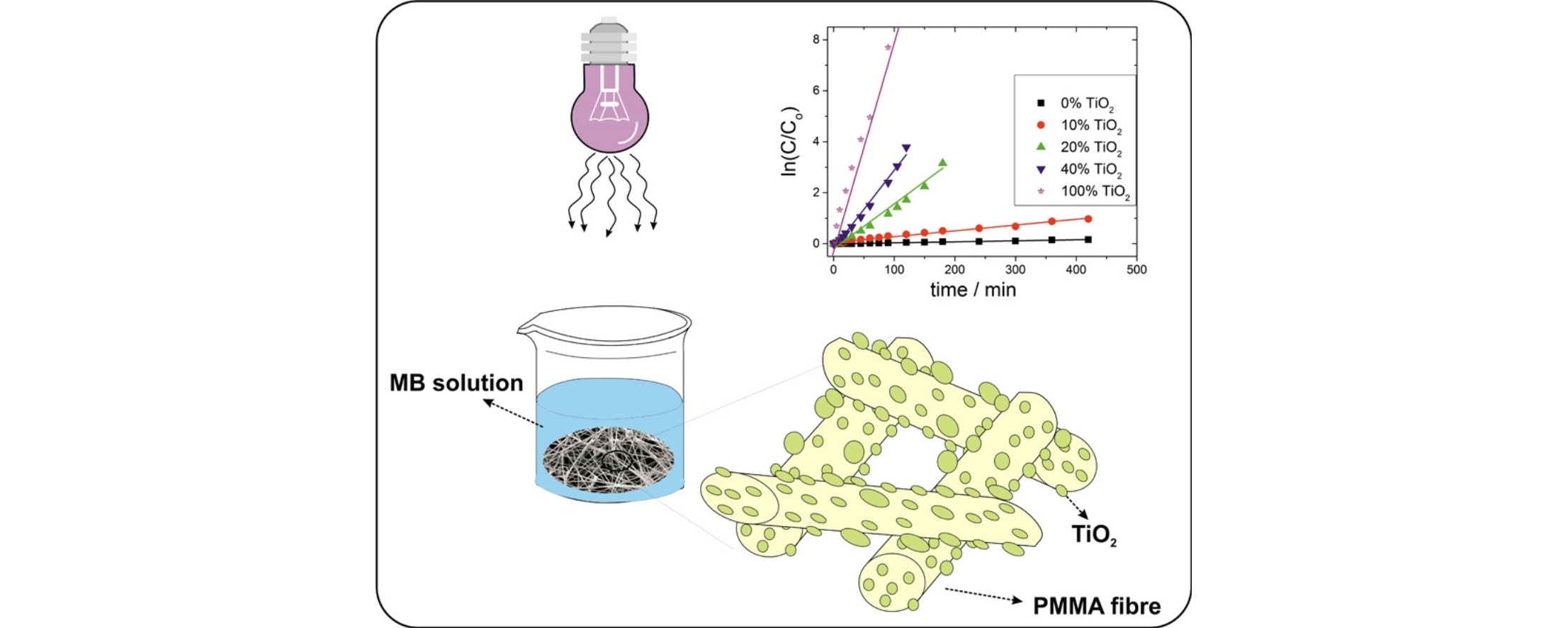

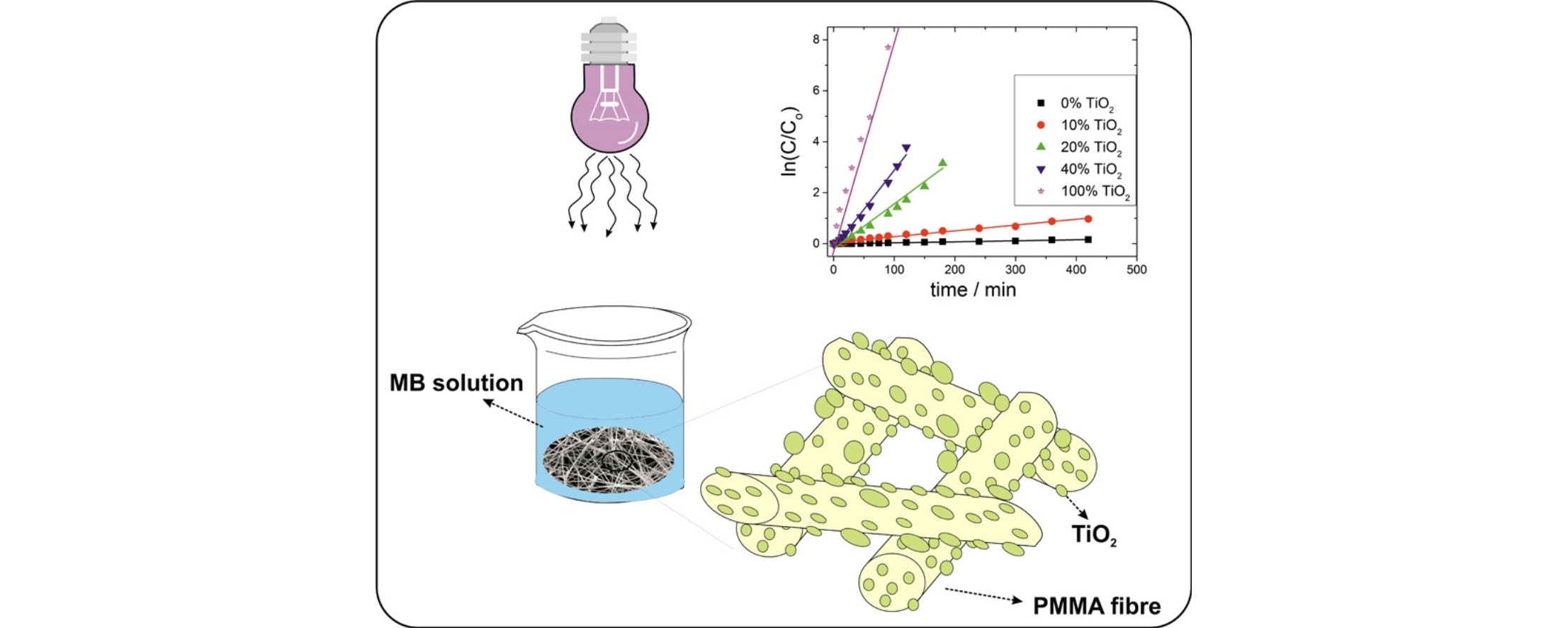

An orthogonal experimental method was designed to assess the influence of the electrospinning processing parameters on average diameter and distribution of poly(methyl methacrylate) (PMMA) fibers. Based on the orthogonal experimental design analysis, electrospun TiO2-PMMA nanocomposites were processed with the optimal polymer processing conditions to obtain thin fibers with a high overall surface area. Further it was found that the average fiber diameter decreases from 2.0 +/- 0.5 down to 1.2 +/- 0.2 mu m with increasing photocatalyst content. Moreover, the wettability of samples was independent of the filler amount, and showed strong hydrophobic behavior. Thermogravimetric analysis showed that for polymer solutions with concentrations higher than 10 wt%, there was a loss of the photocatalytic particles during processing, being more evident for the sample with 40 wt% particles present in the solution, with a loss of 8 wt% of ceramic particles. The immobilization of the TiO2 nanoparticles in the polymer fibers led to an increase of the thermal stability. The photocatalytic performance was assessed by using methylene blue (MB). The nanocomposite electrospun fiber membranes had a remarkable photocatalytic activity, especially the one with higher amount of TiO2, with all the MB dye being removed from the solution after 100 min, under UV. The orthogonal experimental design is an efficient way to save time and materials in the production of photocatalytic membranes. Crown Copyright (C) 2016 Published by Elsevier Ltd. All rights reserved.

An orthogonal experimental method was designed to assess the influence of the electrospinning processing parameters on average diameter and distribution of poly(methyl methacrylate) (PMMA) fibers. Based on the orthogonal experimental design analysis, electrospun TiO2-PMMA nanocomposites were processed with the optimal polymer processing conditions to obtain thin fibers with a high overall surface area. Further it was found that the average fiber diameter decreases from 2.0 +/- 0.5 down to 1.2 +/- 0.2 mu m with increasing photocatalyst content. Moreover, the wettability of samples was independent of the filler amount, and showed strong hydrophobic behavior. Thermogravimetric analysis showed that for polymer solutions with concentrations higher than 10 wt%, there was a loss of the photocatalytic particles during processing, being more evident for the sample with 40 wt% particles present in the solution, with a loss of 8 wt% of ceramic particles. The immobilization of the TiO2 nanoparticles in the polymer fibers led to an increase of the thermal stability. The photocatalytic performance was assessed by using methylene blue (MB). The nanocomposite electrospun fiber membranes had a remarkable photocatalytic activity, especially the one with higher amount of TiO2, with all the MB dye being removed from the solution after 100 min, under UV. The orthogonal experimental design is an efficient way to save time and materials in the production of photocatalytic membranes. Crown Copyright (C) 2016 Published by Elsevier Ltd. All rights reserved.