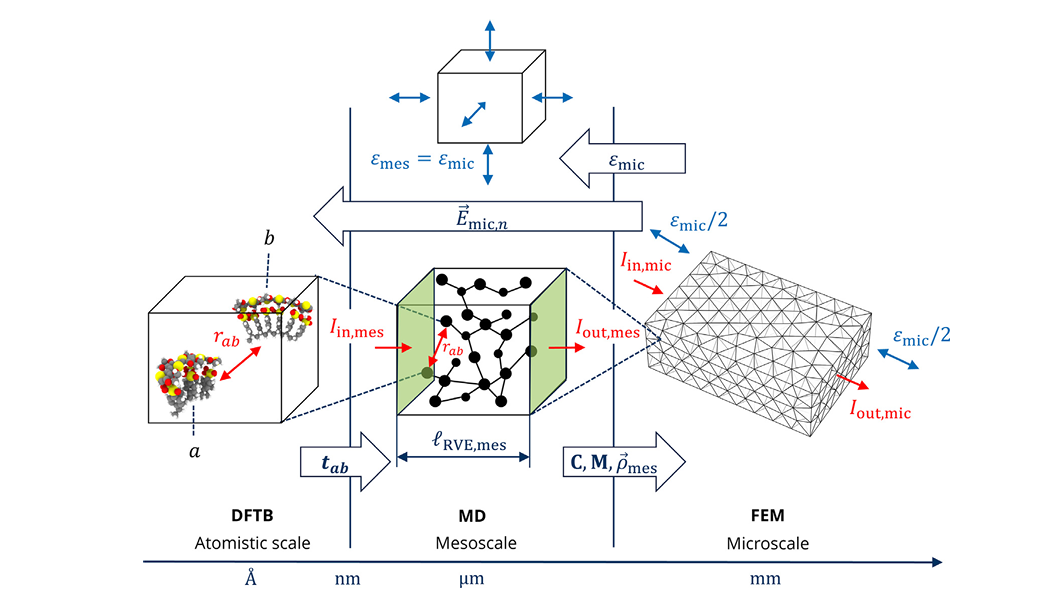

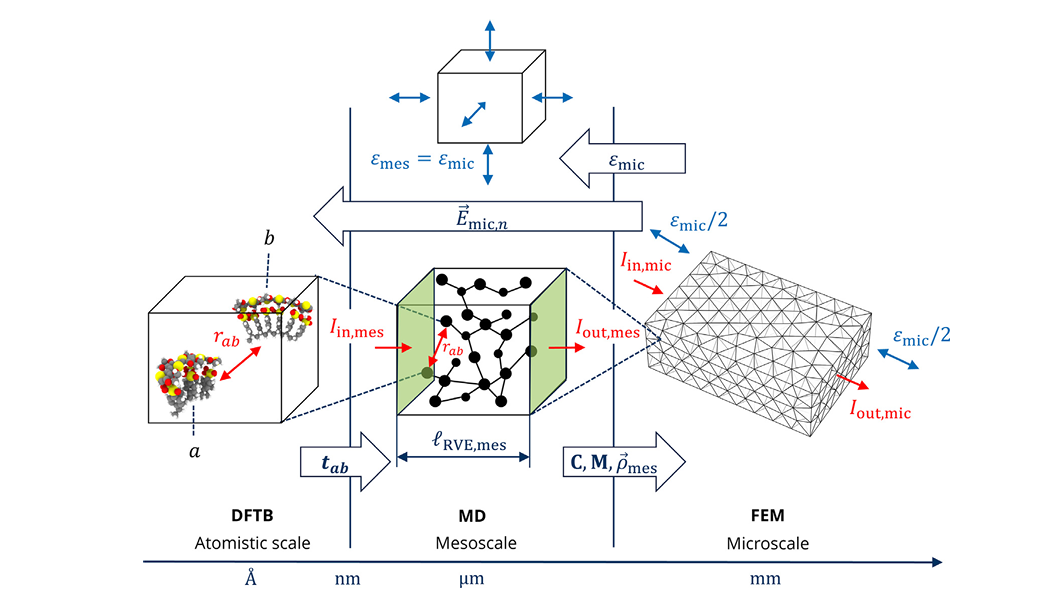

The modeling and simulation process presented in this article enables the coupled consideration of mechanical and electronic properties of amorphous polymer structures based on poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS) at the atomistic scale, mesoscale, and microscale. We use the density functional tight binding method, molecular dynamics simulations (MD), and the finite element method (FEM) to compute the material behavior on multiple scales. Our Python framework Multiscale Mechatronic Material Framework (M3F) is used for in-situ processing, evaluation and exchange of the generated data between the simulation methods. To describe the elastic behavior of the volume element at the microscale using FEM, we first perform compression and tension tests at the mesoscale using MD simulations. At the microscale, the Laplace equation is then solved using FEM and the spatially dependent current density is calculated as a function of the charge carrier hopping rates between the molecular units. Thus, the deformation- and location-dependent calculation of the electrical resistance at the microscale takes into account the orientations of the polymer chains. The multiscale computational process described here represents a computationally efficient evaluation of the mechanical and electronic properties and their interactions at different scales. In addition, this computational simulation framework can also be adapted for different polymers or polymer-based nanocomposites and extended to include different physical models, for example to describe charge carrier hopping or elasticity.

The modeling and simulation process presented in this article enables the coupled consideration of mechanical and electronic properties of amorphous polymer structures based on poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS) at the atomistic scale, mesoscale, and microscale. We use the density functional tight binding method, molecular dynamics simulations (MD), and the finite element method (FEM) to compute the material behavior on multiple scales. Our Python framework Multiscale Mechatronic Material Framework (M3F) is used for in-situ processing, evaluation and exchange of the generated data between the simulation methods. To describe the elastic behavior of the volume element at the microscale using FEM, we first perform compression and tension tests at the mesoscale using MD simulations. At the microscale, the Laplace equation is then solved using FEM and the spatially dependent current density is calculated as a function of the charge carrier hopping rates between the molecular units. Thus, the deformation- and location-dependent calculation of the electrical resistance at the microscale takes into account the orientations of the polymer chains. The multiscale computational process described here represents a computationally efficient evaluation of the mechanical and electronic properties and their interactions at different scales. In addition, this computational simulation framework can also be adapted for different polymers or polymer-based nanocomposites and extended to include different physical models, for example to describe charge carrier hopping or elasticity.