The high tensile strength and high tensile modulus of carbon fibers are due to the unique, alongside the fiber axis preferably oriented turbostratic or graphite-like carbonaceous crystal structure. To achieve certain tensile strengths and tensile moduli of carbon fibers defined structural parameters should be maintained. Copolymers of polyacrylonitrile constitute as a precursor material ca. 90 % of the global carbon fibers market, where the precursor makes roughly 50 % of their costs. Different research methodologies were recently reported about the reduction of the costs of carbon fibers. For instance, heavy tow textile grade acrylic fibers prepared by pseudo-melt spinning technology and stabilized via advanced oxidative stabilization technique, i. e. microwave-assisted plasma, can be utilized to reduce the costs of carbon fibers. Another important aspect of carbon fiber production is the low carbon yield (up to 50 %) of the polyacrylonitrile. This means that the production capacity of PAN-based carbon fiber plants is one-half of that of PAN plants. This implies the necessity to raise the carbon yield of the precursor system used to further reduce the costs of carbon fibers and increase the CO2 balance of the CF. Lignin is a by-product of the pulping process and a cheap material. The high abundance, one-third of the dry weight of the lignocellulosic biomass, and the aromatic character of this material are of paramount importance for further economic utilization for high value-added products, such as carbon fiber precursors. Caused by the pulping process, Lignin shows consistency problematics making it unsuitable for fiber formation, i. e. very low molecular weight and high polydispersity lead to brittleness of the fiber structure, the high ash content leads to defects and flaws in the fine fiber structure. Utilizing lignin as a precursor for high-value-added carbon fibers is not a new research topic. Different research routes were pursued to formulate lignin-based precursor fibers and subsequently lignin-based carbon fibers with high mechanical properties. Up to date, Lignin-based carbon fibers show low mechanical performance, i. e. low tensile strength < 1 GPa, low tensile modulus < 150 GPa, and low elongation at break < 1 %. Up-to-date lignin-based carbon fibers, regardless the PAN/Lignin-based carbon fibers, show low mechanical properties and the achieved properties are inferior to the set targets. The absence of the semi-crystalline structure of lignin prevents the orientation of the molecules alongside the fiber axis during the high shear stress extrusion through fine spinning nozzles and the low thermal stability leads to the foaming behavior of lignin at elevated temperatures.

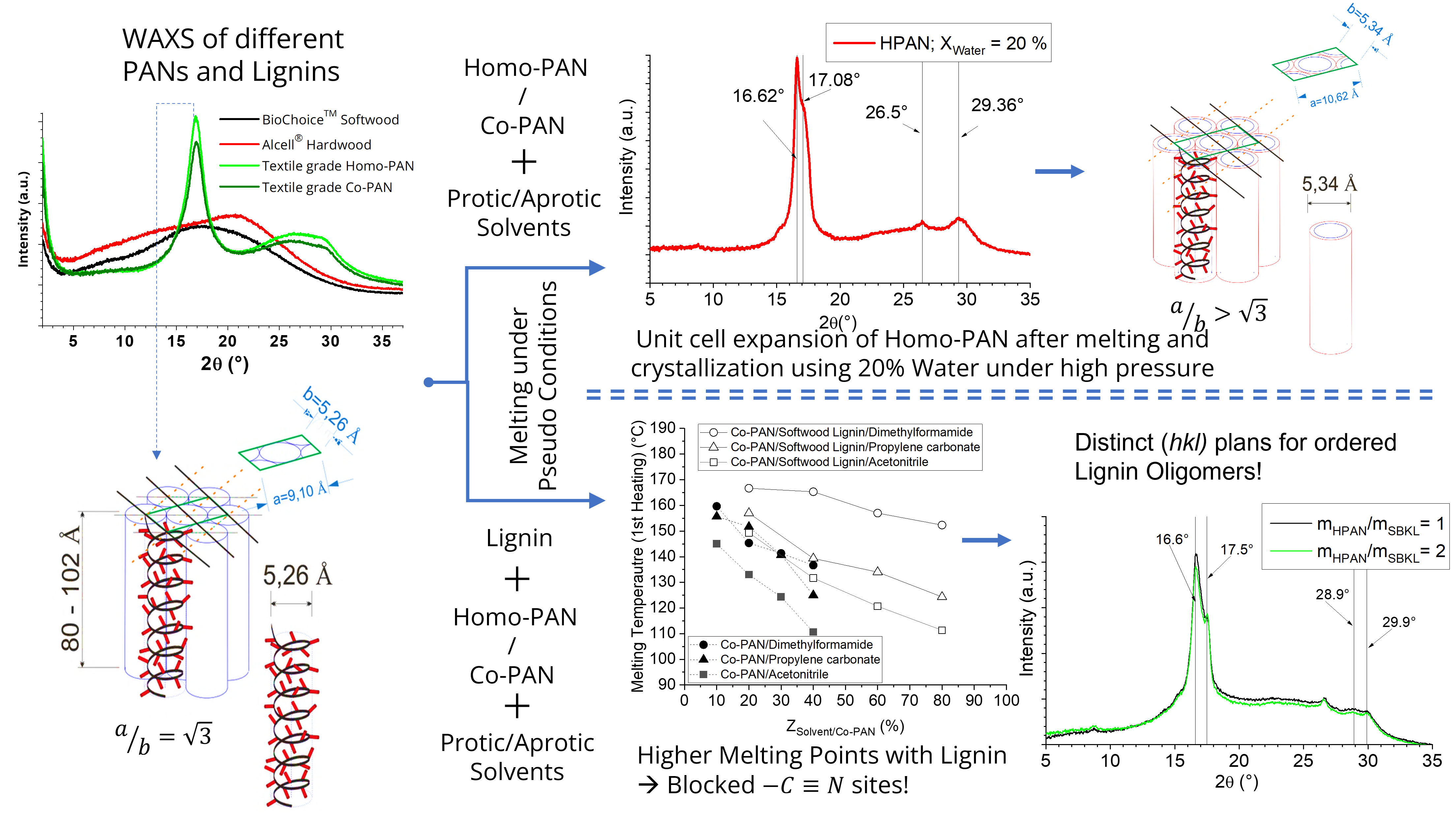

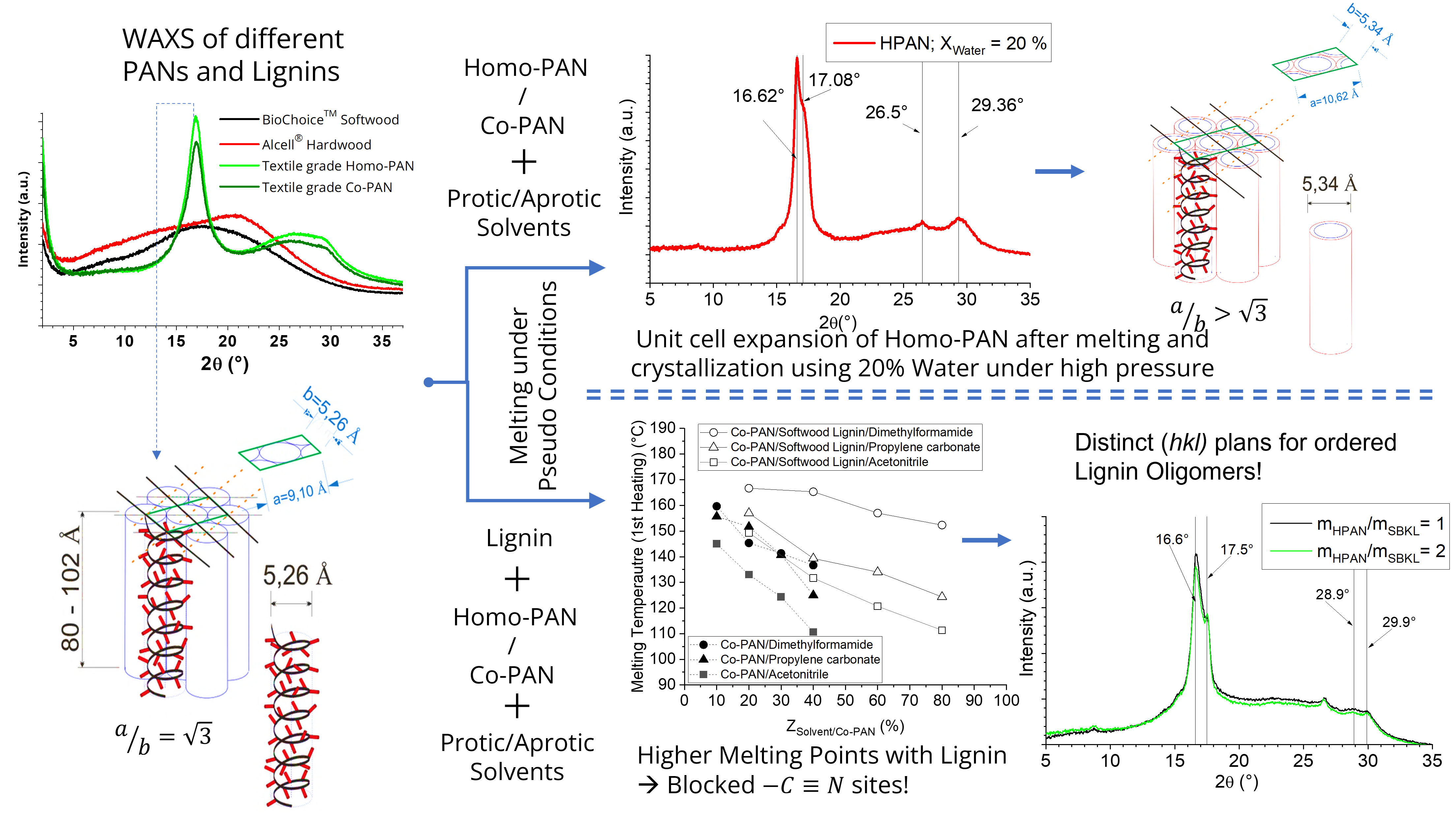

In my talk, I will introduce our findings regarding the co-crystallization behavior of Lignin oligomers from pseudo melts of Polyacrylonitlirle and their Co-Polymers in protic/aprotic solvents. Also, a novel spinning technology for forming fibers out of the pseudo-melts of Lignin/PANs will be presented.

The high tensile strength and high tensile modulus of carbon fibers are due to the unique, alongside the fiber axis preferably oriented turbostratic or graphite-like carbonaceous crystal structure. To achieve certain tensile strengths and tensile moduli of carbon fibers defined structural parameters should be maintained. Copolymers of polyacrylonitrile constitute as a precursor material ca. 90 % of the global carbon fibers market, where the precursor makes roughly 50 % of their costs. Different research methodologies were recently reported about the reduction of the costs of carbon fibers. For instance, heavy tow textile grade acrylic fibers prepared by pseudo-melt spinning technology and stabilized via advanced oxidative stabilization technique, i. e. microwave-assisted plasma, can be utilized to reduce the costs of carbon fibers. Another important aspect of carbon fiber production is the low carbon yield (up to 50 %) of the polyacrylonitrile. This means that the production capacity of PAN-based carbon fiber plants is one-half of that of PAN plants. This implies the necessity to raise the carbon yield of the precursor system used to further reduce the costs of carbon fibers and increase the CO2 balance of the CF. Lignin is a by-product of the pulping process and a cheap material. The high abundance, one-third of the dry weight of the lignocellulosic biomass, and the aromatic character of this material are of paramount importance for further economic utilization for high value-added products, such as carbon fiber precursors. Caused by the pulping process, Lignin shows consistency problematics making it unsuitable for fiber formation, i. e. very low molecular weight and high polydispersity lead to brittleness of the fiber structure, the high ash content leads to defects and flaws in the fine fiber structure. Utilizing lignin as a precursor for high-value-added carbon fibers is not a new research topic. Different research routes were pursued to formulate lignin-based precursor fibers and subsequently lignin-based carbon fibers with high mechanical properties. Up to date, Lignin-based carbon fibers show low mechanical performance, i. e. low tensile strength < 1 GPa, low tensile modulus < 150 GPa, and low elongation at break < 1 %. Up-to-date lignin-based carbon fibers, regardless the PAN/Lignin-based carbon fibers, show low mechanical properties and the achieved properties are inferior to the set targets. The absence of the semi-crystalline structure of lignin prevents the orientation of the molecules alongside the fiber axis during the high shear stress extrusion through fine spinning nozzles and the low thermal stability leads to the foaming behavior of lignin at elevated temperatures.

In my talk, I will introduce our findings regarding the co-crystallization behavior of Lignin oligomers from pseudo melts of Polyacrylonitlirle and their Co-Polymers in protic/aprotic solvents. Also, a novel spinning technology for forming fibers out of the pseudo-melts of Lignin/PANs will be presented.